In the industrial world, power, precision, and efficiency are the cornerstones of reliable operations. Among the many components that keep industrial systems running smoothly, high-pressure gear pumps play a crucial, often underappreciated, role. From hydraulic systems in heavy machinery to lubrication systems in manufacturing plants, these robust pumps ensure consistent performance under demanding conditions.

This article dives deep into the importance of high-pressure gear pumps, exploring their design, functionality, and the reasons behind their widespread application in hydraulic and lubrication systems. Whether you’re an engineer, system designer, or procurement specialist looking to choose the right gear pump manufacturer, understanding the role of these pumps is vital.

What Are High-Pressure Gear Pumps?

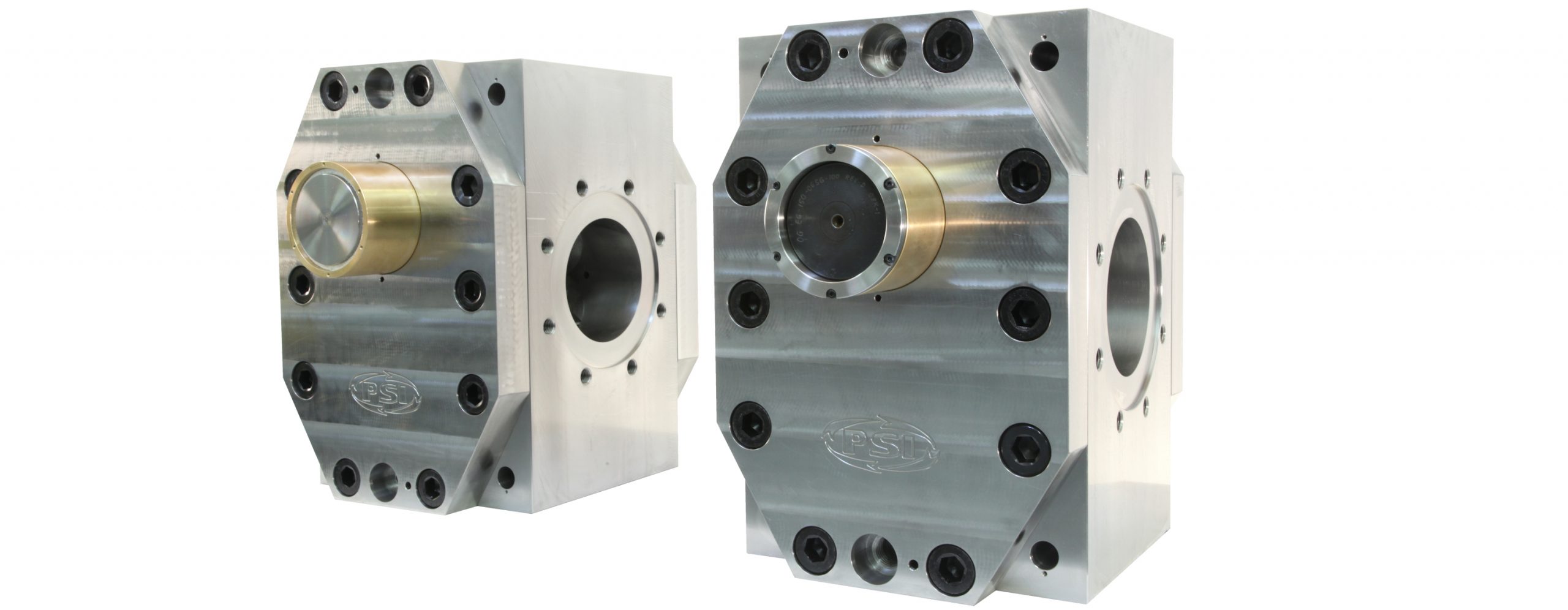

High-pressure gear pumps are positive displacement pumps that use the meshing of gears to pump fluid by displacement. These pumps are designed to withstand and operate efficiently under high-pressure conditions, often exceeding 100 bar (1,450 psi), depending on the application.

Unlike centrifugal pumps, which rely on high-speed impellers, gear pumps deliver a steady flow regardless of system pressure. This makes them particularly suitable for applications requiring precision and consistency.

Core Working Principle

A typical high-pressure gear pump consists of l[gears—driven and idler—enclosed in a housing. As the gears rotate, fluid is drawn into the spaces between the gear teeth and the casing. The fluid is then transported around the outer edges of the gears and discharged when the gears mesh again, creating a smooth and consistent flow.

This mechanism makes gear pumps extremely efficient at handling viscous fluids, such as oils, lubricants, and certain chemicals, which are commonly found in industrial hydraulic and lubrication systems.

Key Benefits of High-Pressure Gear Pumps

1. Consistent Flow Rate

One of the biggest advantages of high-pressure gear pumps is their ability to maintain a consistent flow regardless of pressure fluctuations. This is critical in applications like hydraulic actuators, where precision is non-negotiable.

2. Compact and Durable Design

These pumps are typically compact, making them ideal for applications where space is limited. Their simple, rugged design ensures minimal maintenance and long operational life.

3. Handling Viscous Fluids

High-pressure gear pumps are particularly effective in transferring thick fluids such as gear oil, hydraulic oil, and lubricants. This makes them indispensable in lubrication systems for heavy machinery, compressors, and engines.

4. Pressure Tolerance

As the name suggests, these pumps are built to handle high-pressure conditions, which allows them to be used in high-load industrial applications without performance degradation.

Applications in Hydraulic Systems

Hydraulic systems rely on fluid power to perform a wide range of tasks—from lifting heavy loads to operating industrial presses and construction equipment. High-pressure gear pumps are often the heart of these systems.

Why are they preferred in hydraulics?

- High Power Density: These pumps can generate a significant amount of hydraulic power in a small package.

- Responsiveness: Their ability to respond quickly to system demands ensures seamless control.

- Durability: In high-demand environments like mining or metalworking, equipment is exposed to intense conditions. High-pressure gear pumps provide the rugged reliability needed to maintain uptime.

Some common hydraulic applications include:

- Earthmoving machinery

- Industrial presses

- Material handling systems

- Agricultural equipment

Role in Lubrication Systems

In any mechanical system, proper lubrication is essential to reduce friction, prevent wear, and extend component life. High-pressure gear pumps serve as the core pumping mechanism in centralized lubrication systems, especially where long-distance fluid transport or high-viscosity oils are involved.

Advantages in lubrication systems include:

- High Efficiency at Low Speeds: Essential for delivering oil in systems where variable flow rates are required.

- Temperature Resistance: Capable of operating in extreme temperatures, especially in heavy-duty applications like steel mills or marine engines.

- Minimal Pulsation: Ensures a steady supply of lubricant, reducing the risk of metal-to-metal contact in rotating or sliding parts.

Applications include:

- CNC machines and lathes

- Compressors

- Turbines

- Gearboxes

Choosing the Right Gear Pump Manufacturer

The performance of a high-pressure gear pump is only as good as its build quality. This is why selecting the right gear pump manufacturer is a critical decision.

Here are some factors to consider:

1. Technical Expertise and Experience

Look for manufacturers with a strong engineering background and proven experience in designing gear pumps for a variety of industrial applications.

2. Material Quality

Ensure the manufacturer uses high-grade stainless steel or other corrosion-resistant materials, especially if your system handles aggressive fluids or operates in harsh environments.

3. Customization Capabilities

Industrial needs vary widely. A reliable gear pump manufacturer should offer customization options in terms of flow rate, pressure rating, port size, and material selection.

4. Testing and Certification

High-quality manufacturers subject their pumps to rigorous testing and provide certification to ensure compliance with industry standards.

5. After-Sales Support

Responsive technical support and availability of spare parts are crucial for long-term operational efficiency.

Common Challenges and How to Address Them

Despite their robust design, high-pressure gear pumps can face issues if not properly selected or maintained. Here are a few common challenges:

- Cavitation: Caused by improper inlet conditions, leading to vibration and noise. This can be prevented by ensuring the correct suction head and fluid viscosity.

- Overheating: High-pressure operation can lead to excessive heat buildup. Integrating cooling mechanisms or selecting pumps with appropriate pressure ratings helps mitigate this.

- Seal Wear: Over time, seals can wear out due to pressure and temperature cycling. Choosing pumps with high-quality seals or replaceable components is essential.

Trends and Innovations

With increasing demand for energy efficiency and sustainability, gear pump technology is also evolving. Innovations such as:

- Smart pumps with IoT integration

- Improved materials for higher corrosion resistance

- Modular designs for easy maintenance

…are driving the future of high-pressure gear pump applications. These developments help industries reduce downtime, optimize energy use, and ensure better process control.

High-pressure gear pumps are far more than just mechanical components—they’re vital enablers of productivity, precision, and safety across industries. Whether you’re designing a hydraulic circuit for a piece of heavy equipment or maintaining a lubrication system in a large-scale plant, the reliability and efficiency of these pumps can directly influence system performance.

Selecting a trustworthy gear pump manufacturer with a focus on quality, customization, and service ensures you get the most out of your investment. As industries evolve and the demand for high-performance systems increases, high-pressure gear pumps will continue to be a cornerstone of reliable fluid handling.